Background

The SEMI North America, the Information & Control Committee meets three times per year; spring summer and fall. This year the spring meetings were held on March 25, 26, 27 at SEMI headquarters in Milpitas, CA. The meetings include task forces with leaders from Cimetrix on the GEM 300, ABFI (Advanced Backend Factory Integration), GUI, DDA, CDS task forces as well as the committee meeting on Wednesday. This is a summary of what happened in the task forces I am highly involved in including GEM 300, ABFI and DDA. There were few ballots this last cycle, especially compared to the last meetings.

Note that all ballots that pass in the committee are still subject to a final review by the global SEMI Audit & Review committee, where a ballot can still fail when proper SEMI procedures and regulations are not strictly followed. This is rare in the North America Information & Control Committee but can happen.

GEM 300 Task Force

Ballot 6836A was modified to address issues raised by several voting members at the fall meetings. In this round of voting, the ballot passed with no rejecting votes and some minor comments from me. Ballot 6836A modifies both specifications E87 Carrier Management and E90 Substrate Tracking. In Substrate Tracking, the substrate object now defines a new optional attribute, “AdditionalInfo”. This attribute is used to designate a list of name/value pair information to be used as needed. The existence of the attribute is standardized, but the usage and values for the names in the name/value pair are custom to be used as needed. For example, an equipment handling multiple substrate types can use a name/value pair to distinguish between the different substrate types. In Carrier Management, carrier objects now define a related new optional attribute “AdditionalSubstrateInfoMap” to store the list of name/value pair information for all substrates in a carrier. These new features enable GEM 300 like E90 and E87 standards to be more easily adapted to all types of equipment and applications.

The Japan GEM 300 task force has proposed ballot 7173 to make minor improvements to the text in the GEM E30 standard. The proposed changes have been submitted to other regions including North America for review. None of the changes are technically significant and should not affect existing GEM implementations.

A few new ideas for ballots were also discussed at the task force. Following are some details on two items that were discussed.

The most prominent new discussion proposes changes to the E157 Specification for Module Process Tracking. Currently, adoption for this standard is limited to equipment that have one or more well-defined or virtual process modules. There are many types of equipment outside of Semiconductor Front-End that do not have a clear concept of a process module like equipment with conveyors moving substrates through the equipment. The new ballot would propose modifications to E157 to define a new, similar state model that can be adapted to report processing details for a substrate rather than a process module. This continues a trend at SEMI to make changes to allow for easier GEM adoption in other industries and more types of equipment.

Another ballot proposes some changes to the new ‘well-known’ subordinate standards to the GEM and GEM 300 standards that establishes standardized names for the alarms, data variables, collection events, status variables and equipment constants required by these standards. While these new subordinate standards have not yet been published, a couple changes are under consideration soon once they are published.

DDA (Diagnostics Data Acquisition) Task Force

- Ballot 7174 was approved to update E128 Specification for SML Message Structures with language to include Transport Layer Security (TLS) because Secure Sockets Layer (SSL) has been deprecated by the Internet Engineering Task Force (IETF). E128 is a key standard in Equipment Data Acquisition communication freeze 1 and 2.

- Ballot 7175 was proposed to update E132 Specification for Equipment Client Authentication and Authorization and the E132 gRPC implementation with several issues found while preparing for EDA Vender Test #2.

- Line item #1 introduced the most significant change; a modification to the password hash algorithm to be a binary array instead of a string. A binary array is more appropriate due to the software hash functions available to programmers. This line item failed due to a technical error in the ballot. The line item will be reworked to resolve this technical mistake and other errors that were revealed later in the week during EDA Vender Test #2.

- Line item #2 moves some requirements from E134 to E132 in cooperation with ballot 7176. This ballot adds the requirements to E132 and passed.

- Ballot 7176 was approved to move requirements from E134 Specification for Data Collection Management to E132 in cooperation with ballot 7175 line item #2. This ballot removes the requirements from E134.

- Ballot 7191 approved changes to E179 Specification for Protocol Buffers Common Components. The ballot primarily introduces some optimizations to the protocol buffer usage to avoid sending parameter type information twice. This affects both ParameterValueType and ArrayParameterValue in the protocol buffer implementation. The changes also clarify the handling of 1, 2 and 4-byte integers by separating into unique types in E179.

- A software vendor test #2 was held on the day following the North America Information & Control Spring meetings. Anyone implementing client and/or server software was invited to attend. Instead of testing for standard compliance, the purpose of the vender test was to test interoperability and flush out any remaining issues in the EDA freeze 3 standards. This software vender test session #2 focused on previously untested E132 features from software vender test session #1 and will also include E125 tests. Several companies including Cimetrix attended the vender test session, providing both client and server functionality for testing against each other. Although official results of the test have not yet been made public, the primary issue discovered is that the password hash algorithm needs to be clarified.

- A software vender test session #3 will be held either immediately following the North America Information & Control Summer meetings held in conjunction with SEMICON West in July, or after the Fall meetings in November. This test session will focus on E134 testing. Mid-April the task force will decide when to proceed.

- Future ballots were proposed for E125, E134, and E179 without specific known issues. In addition to the open ballot for E132, the task force can handle making any last minute changes to the EDA standards before EDA freeze 3 is declared.

ABFI (Advanced Backend Factory Integration) Task Force

No ballots were adjudicated in the ABFI task force. Instead, the task force conducted several open discussions.

- A ballot has been approved to proposed modifications to E90 Specification for Substrate Tracking to accommodate equipment that have multiple substrate ID readers. Currently E90 assumes that an equipment only has one type of substrate and therefore one substrate ID reader. As the GEM 300 standards are implemented on more backend equipment, issues like this are revealed and need a standardized resolution.

- A previous proposal, 6840, to create a Specification for Equipment Adoption Criteria for GEM and GEM-Based Standards was cancelled. In its place a new proposal was approved to create a Guide for Equipment Adoption Criteria for GEM and GEM-Based Standards. A guide differs from a specification because it does not include any requirements. The new guide will help anyone implementing GEM technology understand how the vast number of GEM related standards fit together and when they should be used.

- A new activity was introduced to consider handling substrates with topside and bottom-side identification. More to come as the task force investigates this further.

SEMICON West 2024

The next North America Information and Control meetings will be held in conjunction with SEMICON West in San Francisco. The dates will be July 9-11, 2024. Due to the association with SEMICON West, these meeting typically have the most in person attendees.

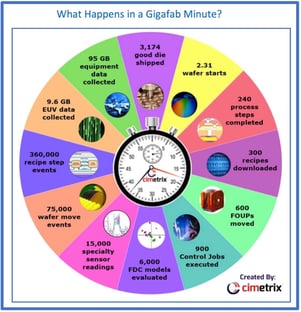

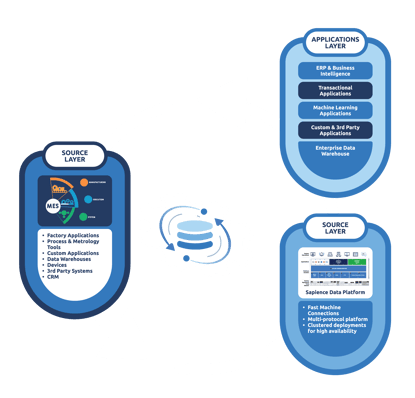

Ripping out and replacing shop floor applications is rarely done. And so, when a fab is built, its data acquisition and control architecture is generally as permanent as the bulk gas transports often seen hulking on the exterior. Modern software architecture has changed dramatically over the last 10 years. Yet the fab and its support systems are relatively static as compared to the process equipment needed to build the latest chips. The result of this imbalance and inertia is that fabs are full of equipment generating oceans of bits and bytes while the managers are struggling to stay afloat and man the oars. This problem only gets worse as management climbs the corporate ladder, or the mast, to extend the metaphor. The people in the corporate suites trying to understand and manage the realities going on in multiple fabs are absolutely inundated and clinging to debris in the deluge. No enterprise-level software system was ever designed to deal with this Noachian torrent of data. Out of this necessity fab managers have been employing data center technology and software architectures more commonly used to run social media sites and Amazon than to run factories.

Ripping out and replacing shop floor applications is rarely done. And so, when a fab is built, its data acquisition and control architecture is generally as permanent as the bulk gas transports often seen hulking on the exterior. Modern software architecture has changed dramatically over the last 10 years. Yet the fab and its support systems are relatively static as compared to the process equipment needed to build the latest chips. The result of this imbalance and inertia is that fabs are full of equipment generating oceans of bits and bytes while the managers are struggling to stay afloat and man the oars. This problem only gets worse as management climbs the corporate ladder, or the mast, to extend the metaphor. The people in the corporate suites trying to understand and manage the realities going on in multiple fabs are absolutely inundated and clinging to debris in the deluge. No enterprise-level software system was ever designed to deal with this Noachian torrent of data. Out of this necessity fab managers have been employing data center technology and software architectures more commonly used to run social media sites and Amazon than to run factories.

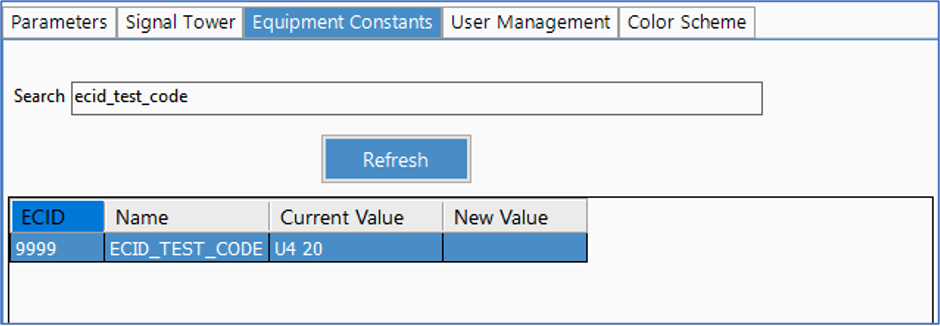

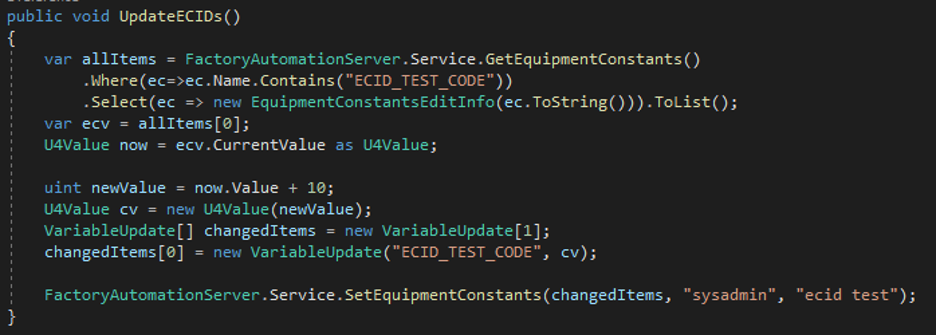

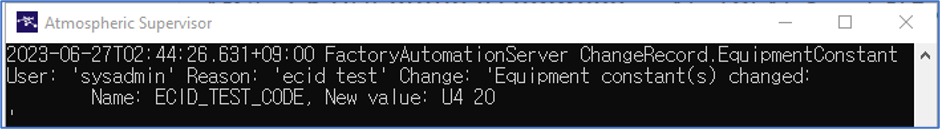

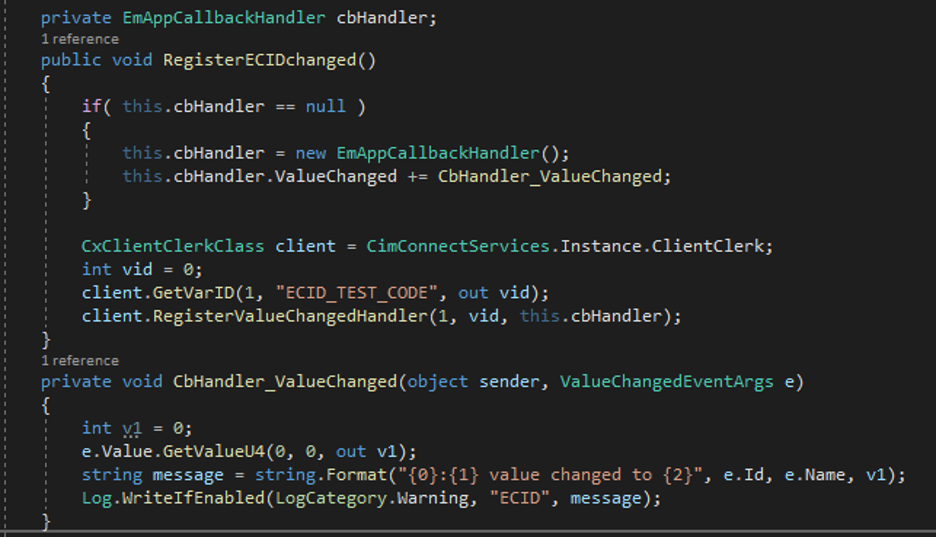

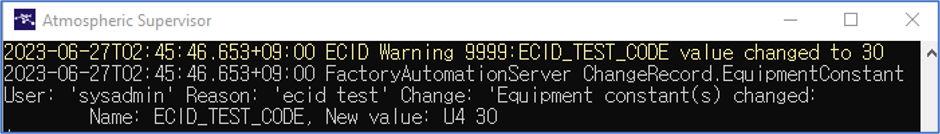

How to change the value of an ECV

How to change the value of an ECV

To Summarize:

To Summarize:

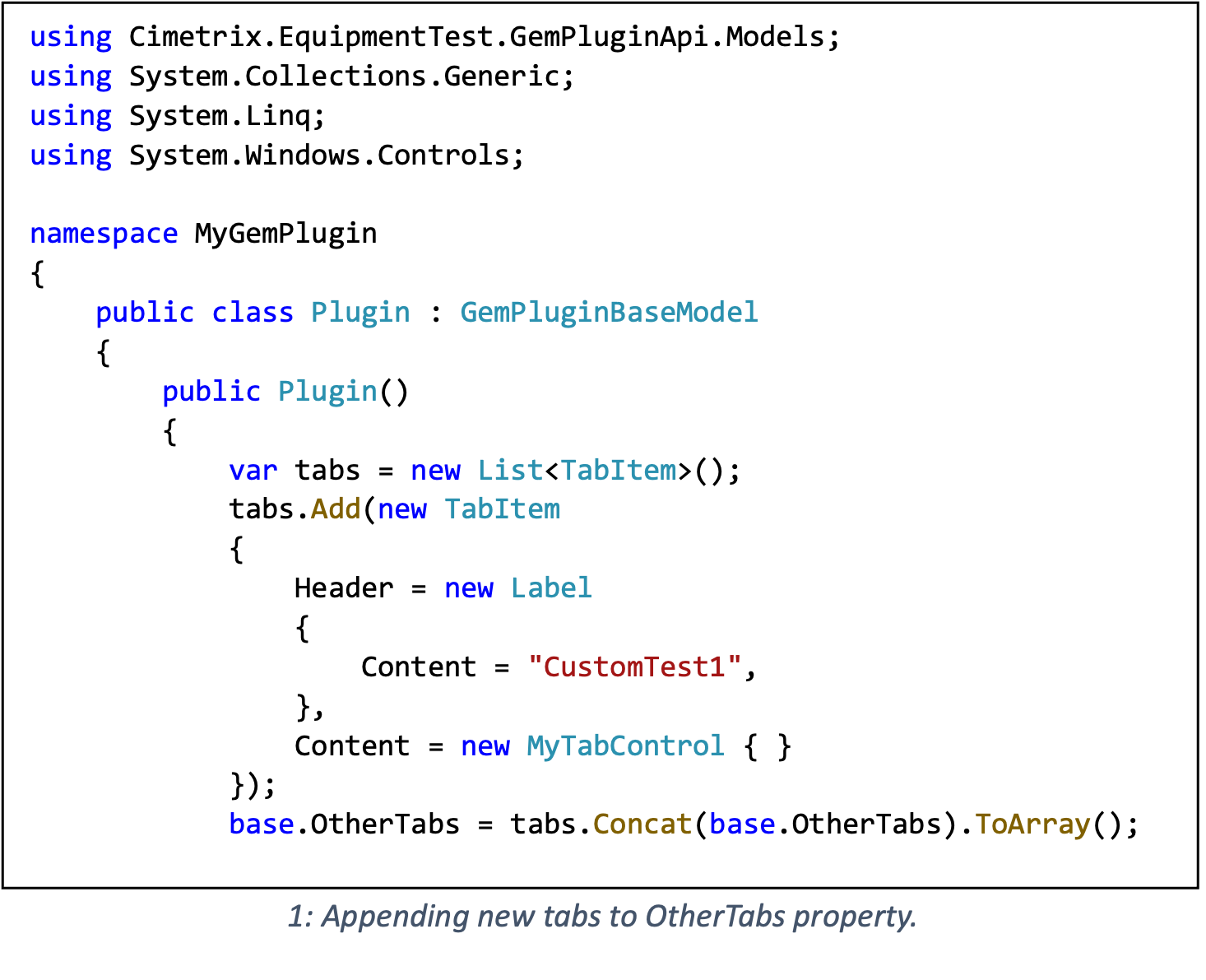

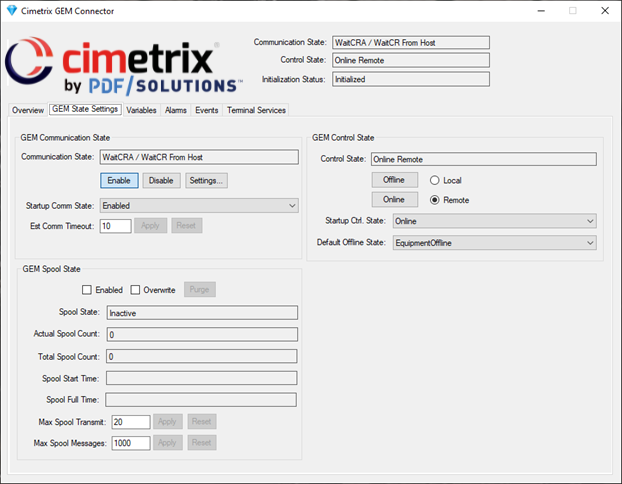

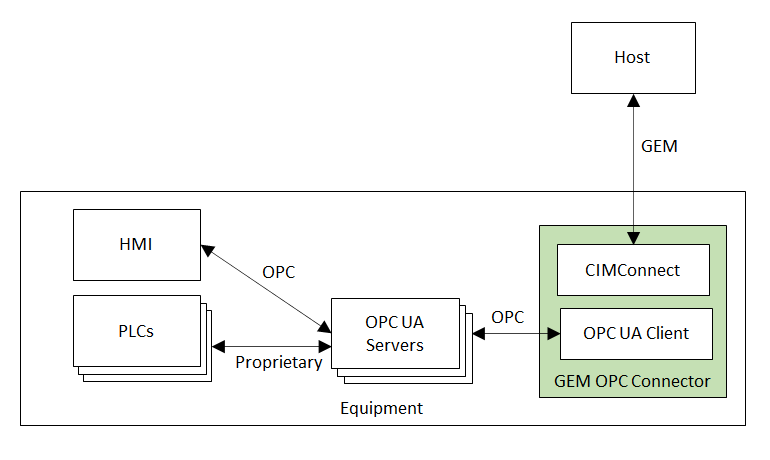

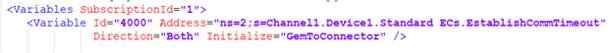

This example links the GEM EstablishCommTimeout equipment constant (VID = 4000) to an OPC UA tag = “Channel1.Device1.Standard ECs.EstablishCommTimeout”. Since equipment constants can be updated by the operator or by the host, the Direction attribute is “Both”.

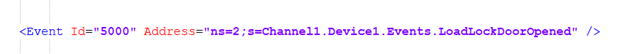

This example links the GEM EstablishCommTimeout equipment constant (VID = 4000) to an OPC UA tag = “Channel1.Device1.Standard ECs.EstablishCommTimeout”. Since equipment constants can be updated by the operator or by the host, the Direction attribute is “Both”. This example links a GEM collection event (CEID = 5000) to a Boolean OPC UA tag = “Channel1.Device1.Events.LoadLockDoorOpened”. The GEM OPC Connector monitors this tag for any value changes, and when the value changes from 0 to 1, it calls a method in CIMConnect to trigger the associated event.

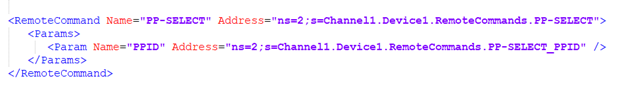

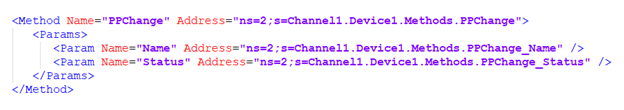

This example links a GEM collection event (CEID = 5000) to a Boolean OPC UA tag = “Channel1.Device1.Events.LoadLockDoorOpened”. The GEM OPC Connector monitors this tag for any value changes, and when the value changes from 0 to 1, it calls a method in CIMConnect to trigger the associated event. This example links the GEM “PP-SELECT” remote command to the Boolean OPC UA Tag = “Channel1.Device1.RemoteCommands.PP-SELECT”. Parameter values are optional. In this case there is a single parameter linked to OPC UA tag = “Channel1.Device1.RemoteCommands.PP-SELECT_PPID”. When the host sends the PP-SELECT remote command using S2F41 “Host Command Send”, the GEM OPC Connector handles the message as follows: if the value of the Processing State is such that the equipment can accept this remote command, the parameter value will be updated first, and then the PP-SELECT value will be set to ”True” to notify the PLC application that the remote command was invoked.

This example links the GEM “PP-SELECT” remote command to the Boolean OPC UA Tag = “Channel1.Device1.RemoteCommands.PP-SELECT”. Parameter values are optional. In this case there is a single parameter linked to OPC UA tag = “Channel1.Device1.RemoteCommands.PP-SELECT_PPID”. When the host sends the PP-SELECT remote command using S2F41 “Host Command Send”, the GEM OPC Connector handles the message as follows: if the value of the Processing State is such that the equipment can accept this remote command, the parameter value will be updated first, and then the PP-SELECT value will be set to ”True” to notify the PLC application that the remote command was invoked.

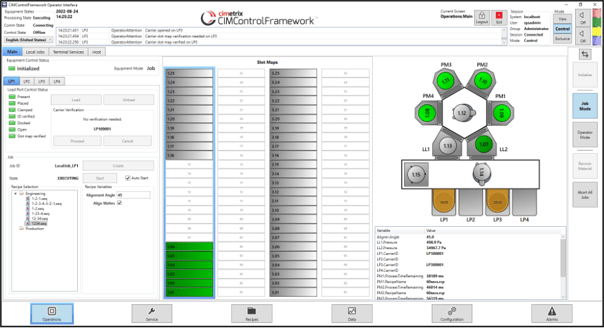

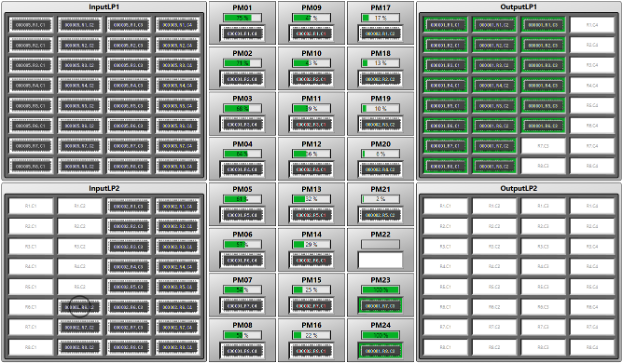

Both visualization examples were created with the same visualization library.

Both visualization examples were created with the same visualization library. These interlocks are generally based on states and are equipment-dependent. Software interlocks are not a replacement for hardware interlocks. Software interlocks are like a safety net—they are not normally needed, but when they are, there is a much lower risk of damage.

These interlocks are generally based on states and are equipment-dependent. Software interlocks are not a replacement for hardware interlocks. Software interlocks are like a safety net—they are not normally needed, but when they are, there is a much lower risk of damage.