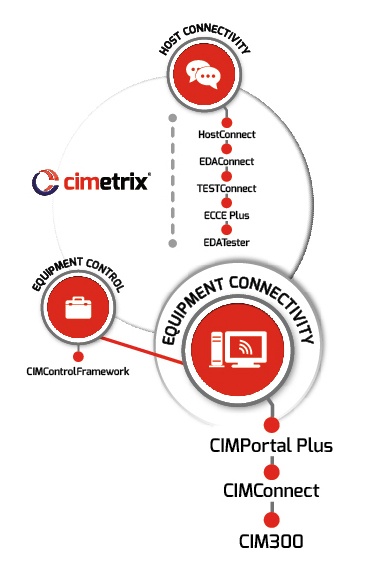

Equipment Connectivity

Equipment connectivity products are used in automated manufacturing equipment to enable them to communicate with the factory information and control systems that run the overall plant. In mature industries, the communications between equipment and factory systems is governed by precisely defined standards that leverage common computing and networking platforms while providing the specific command, control, and data collection capabilities required for efficient and effective operations.

SECS/GEM

The SECS/GEM standard is most widely adopted standard for the range of equipment types in the semiconductor (front end and back end), flat panel display, electronics assembly (PCB fabrication, surface mount technology), photovoltaic, HB-LED, and other similar manufacturing industries. The SECS/GEM standard defines messages, state machines, and scenarios to enable factory software to control and monitor manufacturing equipment. Moreover, because the GEM standard was written with very few semiconductor-specific features, it can be applied to virtually any manufacturing equipment in any industry.

Learn more about the Cimetrix software product that implements SECS/GEM on manufacturing equipment.

GEM300

With the transition to 300mm wafers, the level of factory automation in the semiconductor fabs increased significantly. SEMI introduced the GEM300 standards to allow this dramatic change to be implemented as cost effectively as possible. Compliance with the SEMI 300mm communication standard is no longer optional. 300mm semiconductor factories require equipment suppliers to fulfill the standards in order to implement factory automation.

View the Cimetrix software product that implements GEM300 on manufacturing equipment.

EDA/Interface A

Industry experts developed the EDA/Interface A standards to support the data acquisition performance, flexibility, and data quality requirements for advanced wafer fabs. The stakeholders in these factories use EDA for a wide range of applications, including on-line Fault Detection and Classification (FDC), lot-level and wafer-level APC, equipment and factory throughput optimization, preventive maintenance, yield management, and other factory analytics. These standards complement the SECS/GEM standards, which remain in place for providing MES connectivity.

The EDA/Interface A standards use common networking hardware and software, specifically SOAP/XML messages over an HTTP or HTTPS connection.